Connect with Jay Castle on LinkedIn

HVAC chose me

I didn’t grow up dreaming of HVAC. After graduating from Texas A&M University with an engineering degree, I planned to have a career in the US Air Force. After 8½ years in the Air Force my wife was tired of all the moving around and really wanted to move back home to Texas. I agreed that would be best for my family, so I accepted a job as an engineering salesman for York in Dallas, Tx. I had a wife, two daughters, and another on the way. My first HVAC job wasn’t as good as I expected, but I didn’t feel like I had a choice. I didn’t have the time to reinvent myself, money for law school, or a shot at professional sports. HVAC was it, so I had to figure out how to be good at it.

Skills many don’t get today

I didn’t have strong mentors when I started. My first manager left quickly, and I realized success in this industry comes from taking care of customers and building credibility. That takes time. You don’t get it from a book or a four month class.

At York, I started out selling chillers and air handlers. Later, I joined a company that did 100% custom HVAC. We’d start with a blank sheet of paper, and I had to learn everything: DX units, energy recovery, psychrometrics, electricity. Most of it was self-study, repetition, and ASHRAE resources. Designing systems from scratch and then seeing if they actually worked, you know, “did I make all the right choices when I sized the coil or sized the dampers? Did I write the control sequence correctly?” It gave me skills many don’t get today, now that computers do most of the work. The software just picks everything for you now, but I can still go back and do it by hand if I need to.

Adapting to change

The military shaped the way I work. It taught me to look out for others and to be part of the solution. That mindset carried over directly to HVAC. I see it as my job to make my customers and my employees successful.

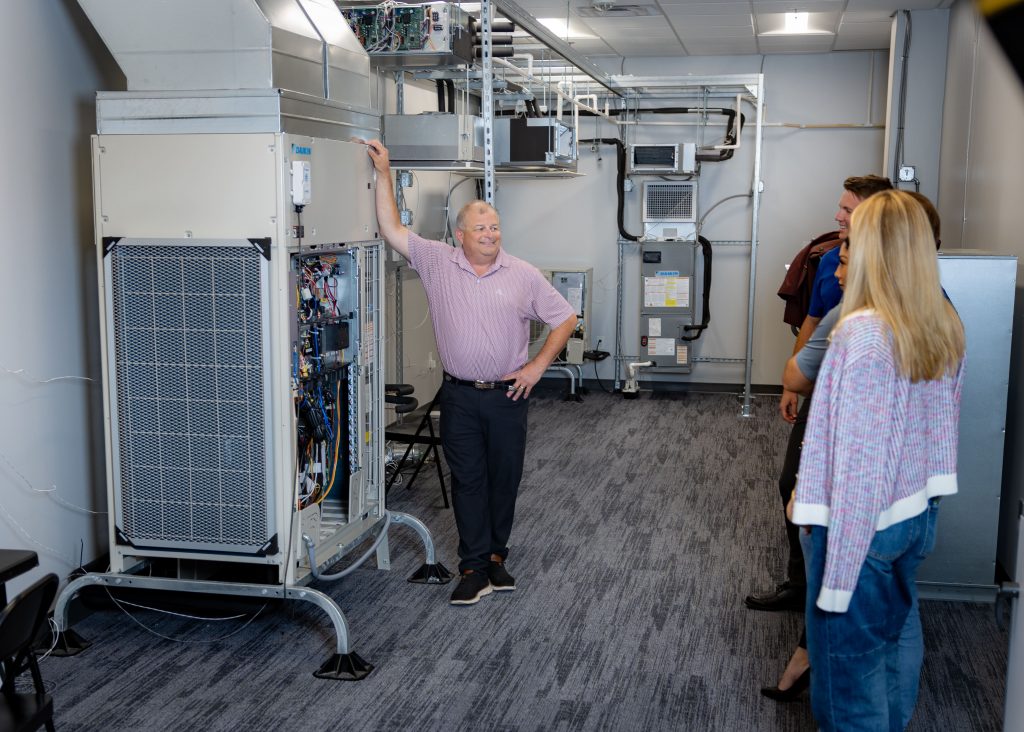

At DXS, our focus is on Daikin’s VRF systems. Over the past few years, ASHRAE updated its safety standards, which could have limited the use of VRF. Being active in ASHRAE, first as a member, then as chairman of Technical Committee, I’ve been directly involved in interpreting new safety research and contributing to code updates.

This work has allowed us to train our sales team, advise factories on field-ready designs, and ensure VRF remains a cost-effective, energy-efficient solution. As we transition from R410A to R32 refrigerants, my experience with these standards and relationships within ASHRAE have made the shift smoother.

Finding creativity in the trade

People don’t always realize how much creativity there is in technical sales. Every building is different, and I get to balance cost, efficiency, and architectural constraints. It’s a great feeling to drive by a building, stay in a hotel I worked on, or see thermostats I specified and know I contributed to something lasting.

Some projects pushed the boundaries: A vivarium, NASA facilities, lithium battery plants, even traveling circuses. One of my favorites was for a former Dallas Cowboy who wanted to replicate Kentucky bourbon conditions in Texas. We had to design a system that swung temperature and humidity just right to mimic aging barrels. That one was fun.

Legacy

What I want to be remembered for isn’t a building or a project, it’s people. I want to be known as someone who stopped what he was doing to give employees the knowledge to succeed. And maybe as someone who made people laugh along the way.